We've capsized!

The parents were in yesterday and helped me flip the boat over. It was super helpful to have some extra hands, especially with all the little barbs from the copper stitching sticking out around the hull. And fortunately, I was the only one who got cut. So, thanks mom and dad!

Fun fact, the sawhorse at the stern of the boat is only slightly wider than the boat, so I'm anticipating tears when I one day knock it off... New sawhorses coming (hopefully) soon!

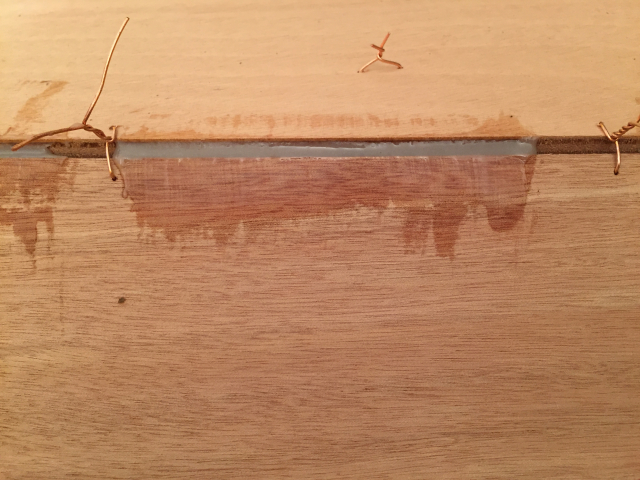

Today Jim and I started gluing the hull panels together. Basically we piped glue into the lapstrakes between the hull panels then cleaned it up with a rubber scraper. Fortunately Jim did some time in a bakery and wasn't too rusty with the icing bag. It went smoothly except that I had no idea how much epoxy to mix at a time, so I was mixing epoxy all the time.

This is part of a seam between the bottom panel and hull panel one. Confession time: I added this picture into the last post because it was the best illustration of stitch and glue that I had. That glue line was done today.

We got about halfway down (two panels), so hopefully this week I can finish gluing the panels together and be ready to flip the boat back for interior epoxy fillets and fiberglass!

(Clever signoff)